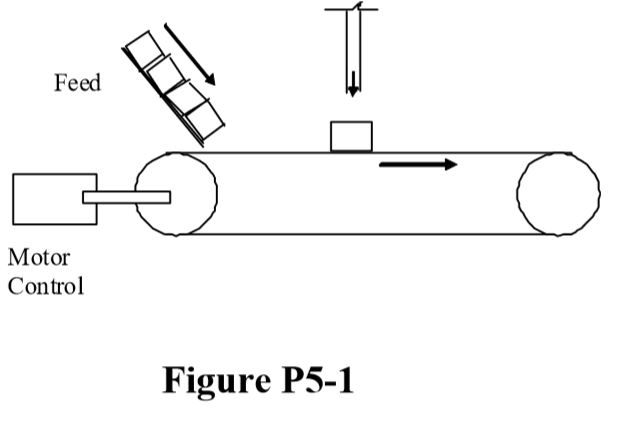

A bottling plant uses an automated mechanism for filling the containers and transporting them from one point to another as shown in Figure P5-1. The sensors monitor the amount of solid or liquid filled. A conveyor mechanism transports the containers. Design a mechatronic system for the case described. Identify the types of sensors you used, describe how they work, explain how you are going to interface and control them. Make suitable sketches if needed.

What will be an ideal response?

A typical answer may contain the following information:

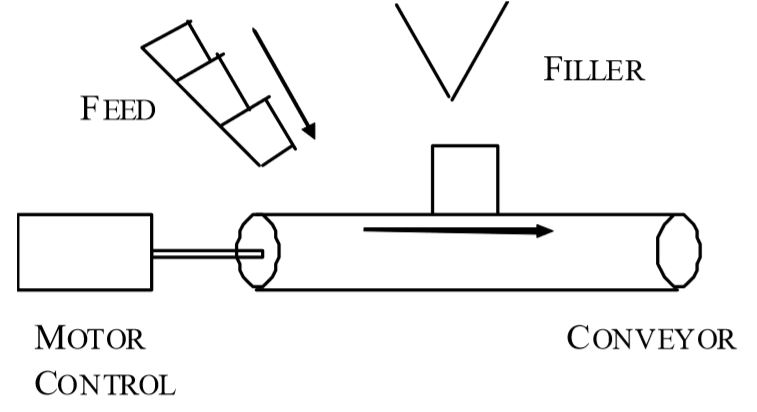

Basically, the purpose of the whole mechanism is to fill a container one at a time and once filled up, move the container to another point at the same time delivering another empty container to be filled in.

i. The container is delivered to the conveyor by a feeder (as shown on the figure above). As soon as one container is placed on to the conveyor, the motor controller will move the conveyor (with the container on it) towards the filler.

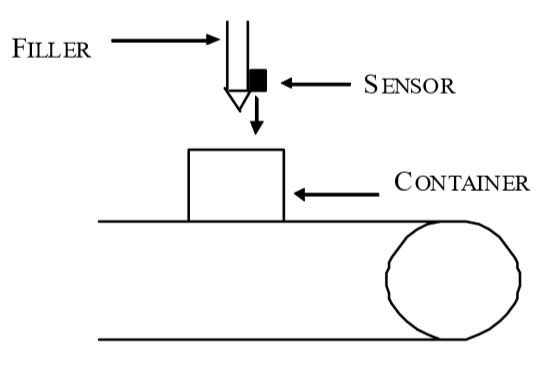

ii. The presence of this container is sensed by a sensor and as soon as it is directly located underneath the filler the sensor transmits a signal to the controller to stop the conveyor. When the conveyor is stopped, the sensor signals the filler to begin filling up the container. (See figure below).

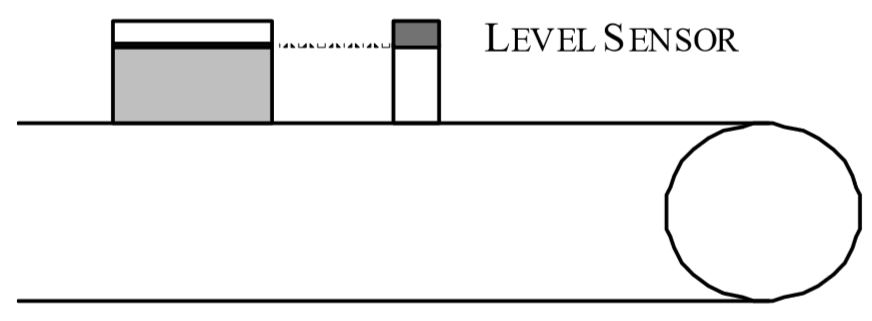

iii. Another sensor is needed to sense the amount being filled in the container. When the desired level is reached, this sensor will send a signal for the filler to stop filling and then for the motor to start the conveyor again.

Sensors and Controllers

If the level is high, the sensor output is “1”. If the level is low, the sensor output is “0”. If the sensor = 1, the conveyor =1 (move). If sensor output is zero, the conveyor stops.

A photoelectric sensor or an infrared detector can be used. If optical sensors are used, when the beam is disturbed by the presence of the container, the sensor sends a signal to the controller and the filler. (For measuring the level of the container, a Hall effect sensor can also be used).

Stepper motors can be used to control the movement of the conveyor. Whenever the sensor reads “1”, pulses are sent to close the switch, so that the motor rotates enough steps to make the conveyor move by one bottle space. Whenever sensor reads “0”, pulses are sent to open the switch, so that the conveyor stops.

You might also like to view...

If an overload relay that is a thermal type has tripped several times, what is the likely cause of the problem?

What will be an ideal response?

In two-conductor cable, the ungrounded or hot wire is _____.

a. green b. red c. black d. grey

What units are used to measure air velocity?

What will be an ideal response?

When AC voltage is rectified and converted into DC, the resulting waveform is normally not pure, flat DC. The pulses that occur are called _____.

A. harmonics B. cosines C. ripples D. peaks