A CNC machine tool table is powered by a servo motor, lead screw and optical encoder. This lead screw has a pitch of 5mm and is connected to the motor shaft with a gear ratio of 16:1 (16 turns of the motor for one turn of the lead screw). The optical encoder is connected directly to the lead screw and generates 200 pulses per revolution of the lead screw. The table must move a distance of 100mm at a feed rate of = 500mm/min. Determine (a) pulse count received by the control system to verify that the table has moved exactly 100mm, (b) pulse rate, and (c) motor speed that corresponds to the feed rate of 500mm/min. If the range of the work table axis is 500mm and there are 12 bits in the binary register used by the digital controller to store the position, determine the control resolution.

What will be an ideal response?

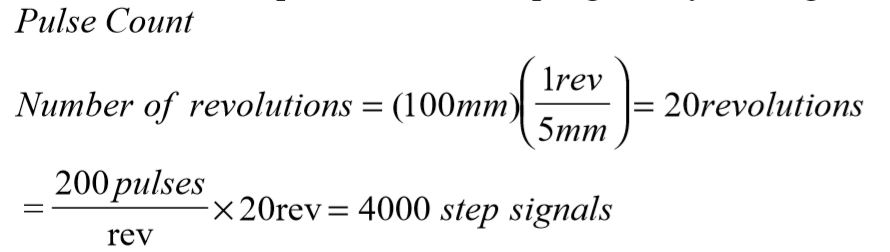

First calculate the pulse count or step signals by finding the number of revolutions.

100mm movement has happened with a feed rate of 500mm/min. In other words, it took 12secs to move 100mm

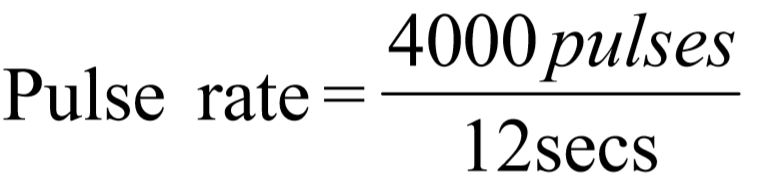

The revolutions can be calculated by knowing revolutions (20) and the time it takes (12sec).

You might also like to view...

Some machines that use this print process allow the user to reduce or enlarge prints to suit specific needs.

a. blueprint b. diazo c. photocopy d. microfilm

How is field wiring shown on most diagrams?

A) In red B) In blue C) With solid lines D) With dashed lines

How many scales does a triangular architectural ruler have?

A) 5 B) 11 C) 8 D) 12

A solution that has more negative ions then positive ions is __________.

A. acidic B. alkaline