List five welding defects in GMAW welding and explain what could cause each of them.

What will be an ideal response?

Porosity has multiple causes; one common condition in collision repair is the formation of hydrogen gas during the welding process because of contamination.

Undercutting can be caused by such conditions as arc length too long, improper gun angle, and weld speed too fast.

Improper fusion can be caused by low or inadequate heat, poor weld technique, insufficient gap, or improper edge set-up.

Overlap may occur from too slow a welding speed or torch feed, among other reasons. The causes of insufficient or poor penetration include welding current too low, arch length too long, improper weld technique, and improper joint fit-up.

You might also like to view...

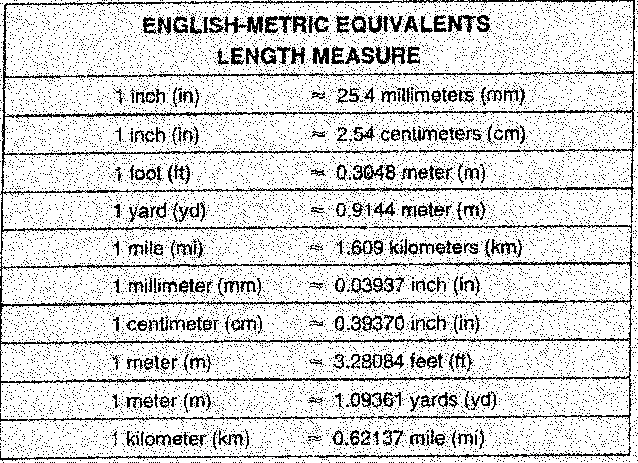

A piece of plate stock that is 2.14’ wide is how wide in meters? Round the answer to the nearest hundredth.

What is the main factor effecting the power output of a solar cell?

What will be an ideal response?

It is unfair to _________

A) Allow others to fail for you B) Allow someone to continue to succeed C) Allow someone to continue to fail D) All of the above

Which of the following is typically not found in the title block?

a. Scale of the drawing b. Signature of the drafter and date completed c. Name of the manufacturer company d. Primary stock material e. Name of the object being drawn