What is the purpose of the revisions block?

What will be an ideal response?

Sometimes, after a drawing has been released to a production department, it is necessary to make design revisions. This may be for design improvement, errors found in the original drawing, production problems, or other reasons. These changes must be approved and shown on the drawing in what is known as a revisions or change block. It is usually located to the left or above the title block. Typically, the entry includes a brief description of the change and an identifying letter referencing it to the specific location on the drawing and the date. The initials of the draftsperson making the change and those approving it are required.

You might also like to view...

Which of the following terms best describes the idea that a nation's trade policy is restrictive, limiting the amount of imports from other countries?

A) Protectionism B) Nationalism C) Mercantilism D) None of the abov

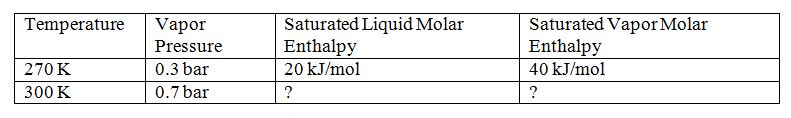

A) Find the rate at which work is added in the compressor, in kJ/min. B) Find the coefficient of performance of the refrigeration cycle. C) Find the specific enthalpy of the refrigerant when it is a saturated liquid at 300 K. D) All of the work for the compressor is supplied by a Rankine heat engine that has an efficiency of 25%. Find the rate at which heat is removed from the condenser in this Rankine heat engine.

3. A steady state refrigerator operates on the vapor compression cycle. The refrigerant, in the vapor phase, behaves as an ideal gas with CP*=6R, and the specific enthalpy of the compound in saturated liquid and saturated vapor states at 270 K is given in the table below.

• The flow rate of the refrigerant is 100 mol/min.

• The vapor entering the compressor is saturated vapor at 270 K.

• The efficiency of the compressor is 75%.

• The liquid exiting the condenser is saturated liquid at 300 K.

• The mixture exiting the valve is 20% vapor and 80% liquid.

• There is no significant pressure change in either heat exchanger.

Discuss how an object line is drawn.

What will be an ideal response?

Of the following metals often found in sewage sludge, which would most likely become toxic to farmers' crops if sludge applications exceeded the recommended amounts?

A) Hg B) Cr C) Cd D) Cu E) Pb