Use this information for questions that refer to the United Tools case.Terry Harter is marketing manager for United Tools, and Mike O'Reilly is the firm's logistics manager. They work together to make decisions about how to get United's hand and power tools to its customers-a mix of manufacturing plants and final consumers (who buy United tools at a hardware store). United Tools does not own its own transport facilities, and it works with wholesalers to reach its business customers.Together, Harter and O'Reilly try to coordinate transporting, storing, and product-handling activities to minimize cost while still achieving the customer service level their customers and intermediaries want. This usually requires that United keep an inventory of most of its products on hand; but demand for

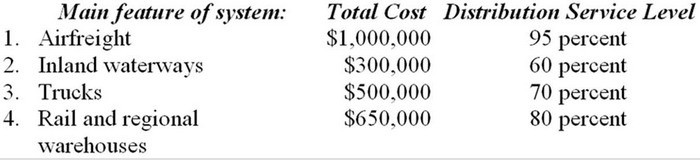

its products is fairly consistent over time, so inventory is easy to manage.Harter has identified four options for physical distribution systems she could use to reach two of her key wholesalers, Ralston Supply and Ricotta Tool Co. The total cost for each option-and the distribution service levels that can be achieved-are as follows: Ralston Supply expects a very high level (90 percent) of distribution customer service. Ricotta Tool Co. is willing to settle for a 70 percent customer service -leveleven if that means some products will occasionally be out of -stockif it gets products at a lower price.For its large retail hardware customers (like Home Depot), United regularly ships smaller orders directly to individual stores or in some cases to the retail chain's warehouses. Cross-country shipments usually go by rail, while regional shipments usually go by truck. United ships to the regional distribution centers of one of the retail hardware chains that it serves. The main advantage of the distribution centers for the retailer is likely to be that they

Ralston Supply expects a very high level (90 percent) of distribution customer service. Ricotta Tool Co. is willing to settle for a 70 percent customer service -leveleven if that means some products will occasionally be out of -stockif it gets products at a lower price.For its large retail hardware customers (like Home Depot), United regularly ships smaller orders directly to individual stores or in some cases to the retail chain's warehouses. Cross-country shipments usually go by rail, while regional shipments usually go by truck. United ships to the regional distribution centers of one of the retail hardware chains that it serves. The main advantage of the distribution centers for the retailer is likely to be that they

A. can store a larger inventory than in traditional warehouses.

B. speed the flow of tools from the factory to the stores.

C. eliminate the need for electronic communications between the distribution centers and the individual stores.

D. None of these is an advantage of distribution centers.

Answer: B

You might also like to view...

In terms of trade areas, the owner of Bubba's Bar and Grille defines his ________ as the geographic area in which 70 percent of his customers live.

A. secondary trading area B. geographic market C. tertiary trading area D. fundamental market E. primary trading area

The stronger the agreement with and commitment to the achievement of the group’s ______, the higher the cohesiveness of the group.

a. strategy b. plan c. culture d. objectives

A manager who excels in maintaining a committed and skilled set of employees is a master at identifying talent as well as hiring and coaching those employees.

a. True b. False

The following data have been provided by Liggett Corporation: Budgeted production 7,400unitsStandard machine-hours per unit 6.6machine-hoursStandard lubricants rate$3.50per machine-hourStandard supplies rate$2.00per machine-hour Actual production 7,600unitsActual machine-hours (total) 49,840machine-hoursActual lubricants cost (total)$179,821 Actual supplies cost (total)$98,933 Lubricants and supplies are both elements of variable manufacturing overhead.The variable overhead rate variance for supplies is closest to:

A. $1,387 F B. $1,387 U C. $747 F D. $640 F